CORA

Located within Barcelona’s Collserola Natural Park, the 135-hectare Valldaura Labs Campus of the Institute for Advanced Architecture of Catalonia (IAAC) is renowned for integrating cutting-edge technologies into sustainable design. Continuing this tradition, the campus recently introduced a KUKA industrial robot—capable of milling, wood-cutting, and other precision tasks.As part of the Master in Advanced Ecological Buildings and Biocities (MAEBB) program, I joined an international team of students tasked with designing and constructing a fully functional laboratory for the robot. The project was completed in just four months, combining hands-on construction with an exploration of ecological and technological integration.

The project was designed to house a 6-axis industrial milling robot within a timber-framed space. With skylights and a calm, cathedral-like atmosphere, it pays homage to both craftsmanship and technology. The building is named CORA — Cathedral of Robotic Artisans.

The project sought to create a dialogue between the building’s original 19th-century brick structure—once a horse stable—and a new timber volume embodying contemporary 21st-century design. The addition was carefully designed to integrate the necessary spaces, services, and infrastructure to support both robotic functions and human interaction.

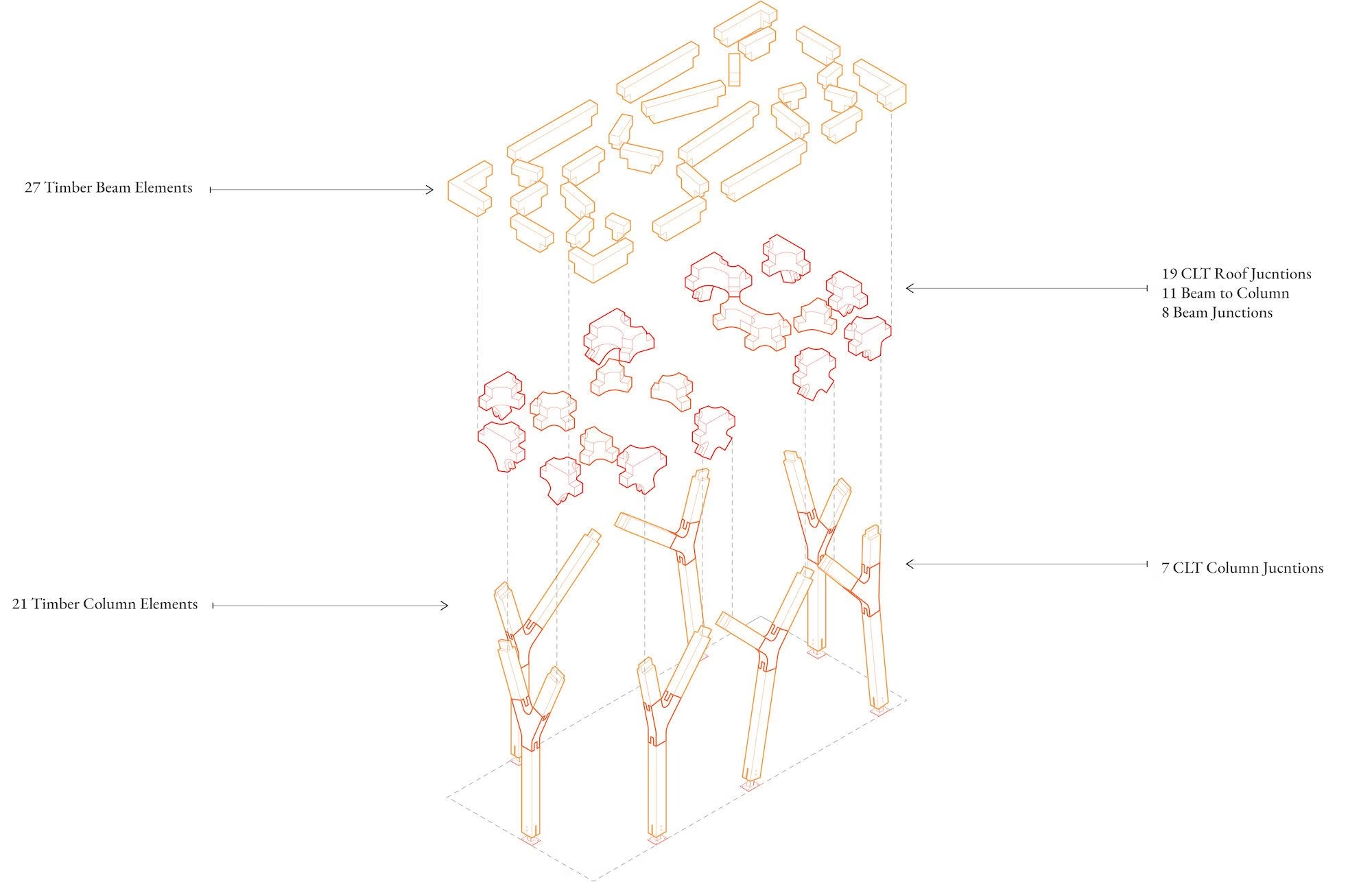

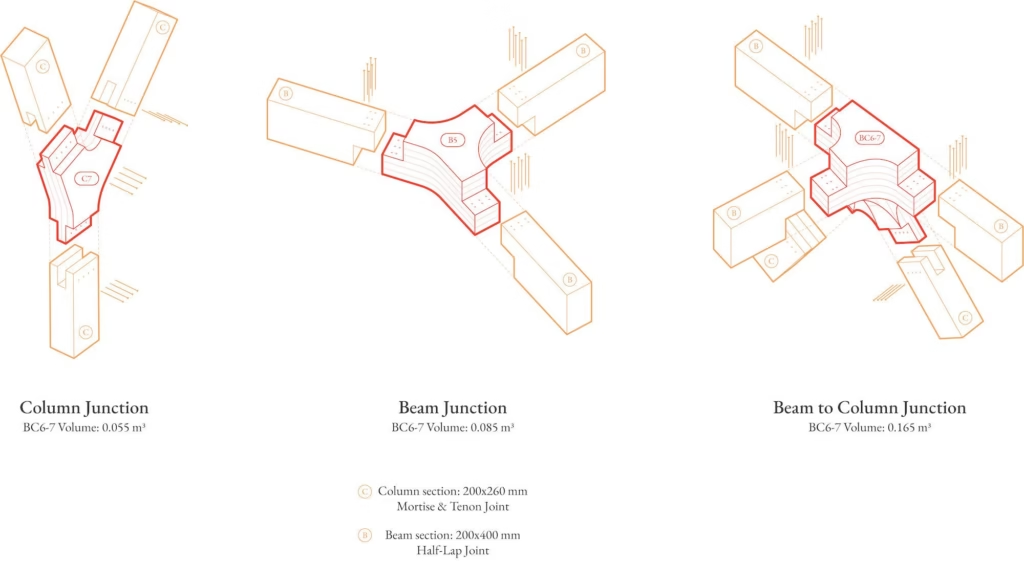

Inspired by the form of a tree, the structure is defined by seven branching wooden columns that evoke trunks rising from the ground. These support a roof composed of solid wood elements joined using Voronoi-patterned geometry and cross-laminated timber (CLT) connections. Precisely fabricated through CNC machining, the carpentry enables the structure to span 8.8 by 4.6 meters. All CLT joints were produced on-site at the Valldaura Campus Labs.

At its core, The Grain explores the interdependence of water and a rice plant, symbolizing the balance of life. Its expansive roof surface is designed to collect and manage water efficiently, integrating water management into the building’s functionality. This feature not only addresses climate resilience but also fosters a meaningful interaction between the structure and its users.

Some joints were milled in four separate layers due to CNC depth limits, then laminated into solid elements. These form a seamless structure that hosts workshop spaces and supports a green roof. Combining traditional carpentry with digital fabrication, solid wood columns (200 x 260 mm) and beams (200 x 400 mm) were assembled off-site, lifted by crane into the brick shell, and anchored to the ground.

Featured Projects

Inspired by our work?

Please fill out the form, so we can learn more about you and your needs.